High Temperature Penetrant Testing

High Temperature Penetrant Testing

Testing is a reliable process used to evaluate the behavior of metal materials when subjected to a combination of high heat and tension. High temperature tensile testing services are performed routinely in many industries for assessing high performance steel and other metals that will be exposed to high temperatures while in service, including nickel alloys intended for jet engines and power generation gas turbines.

Efficient And Reliable High Temperature Testing

Laboratory Testing Inc. near Philadelphia, PA (USA) has capabilities and qualifications not found at many commercial test labs. The elevated temperature tensile test is NADCAP and A2LA accredited and completed according to ASTM E21, which determines tensile strength, yield strength, elongation, and reduction of area of metallic materials at elevated temperatures.

LTI performs high temperature tensile testing on a machine with a furnace carousel that heats up to three specimens at the same time for efficiency and fast order turnaround. The test can be completed at temperatures up to 1800°F.

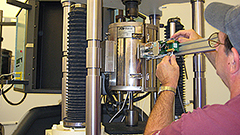

An extensometer connected to the specimen enhances reliability and increases the capabilities of the elevated temperature test system. It provides improved repeatability and curve accuracy, as well as the ability to test a wider range of specimen sizes and a broader range of samples, including sheet and tubing.

More Services To Make Testing Easy

Our full-service mechanical testing lab offers services to fully assess the mechanical properties of your metallic materials, including strength, hardness, ductility, impact resistance, fracture toughness, elongation and stress.

Specimens for all mechanical testing are quickly prepared by our on-site machine shop. Two work shifts are fully staffed with highly trained and skilled CNC machinists and equipment operators. Machining is accredited and performed to industry specifications. Our specimen machining services are also available to prepare special-order specimens for our customers’ in-house testing.

Test Methods/Specifications

- ASTM E21

LTI’S Test Process

When performing elevated temperature tensile testing at Laboratory Testing Inc., the specimen is placed inside a furnace capable of heating to 1800°F. Our computer-controlled system heats the specimen to the required temperature, then allows it to soak. During the next step, the specimen is loaded into the test frame, where an extensometer measures the strain on the specimen as the load is increased. The stress/strain curve and all data are recorded by the fully-computerized system and summarized in your Certified Test Report.

LTI Capabilities

- Temperatures – up to 1800°F

- Materials Tested – metals

- Test Specimens – prepare by LTI’s machine shop